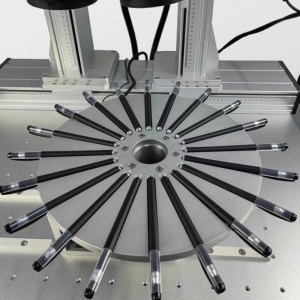

Ceramic core

Firstly, it has excellent wear resistance and can maintain good performance during long-term use. It is not prone to wear and deformation, greatly extending the service life of the product.

Its excellent corrosion resistance enables it to work stably in various harsh environments without being eroded by chemical substances, ensuring the reliability of the product.

The thermal stability of the ceramic core is excellent. Whether in high-temperature or low-temperature environments, it can maintain the stability of size and the consistency of performance, and the working effect will not be affected by temperature changes.

Furthermore, it has precise filtering performance, can effectively filter impurities, provide pure material transmission, and meet the needs of high precision.

Moreover, the surface of the ceramic core is smooth, not prone to bacterial growth and dirt accumulation, and is easy to clean and maintain, saving you time and effort.

In conclusion, the ceramic core brings you an efficient and high-quality use experience with its characteristics of wear resistance, corrosion resistance, thermal stability, precise filtering and easy cleaning.