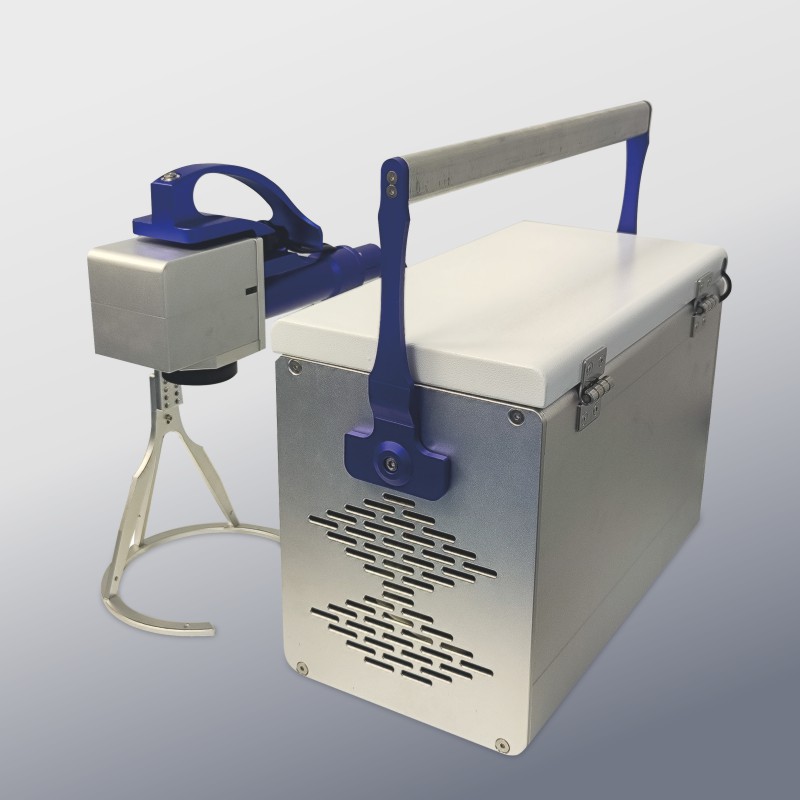

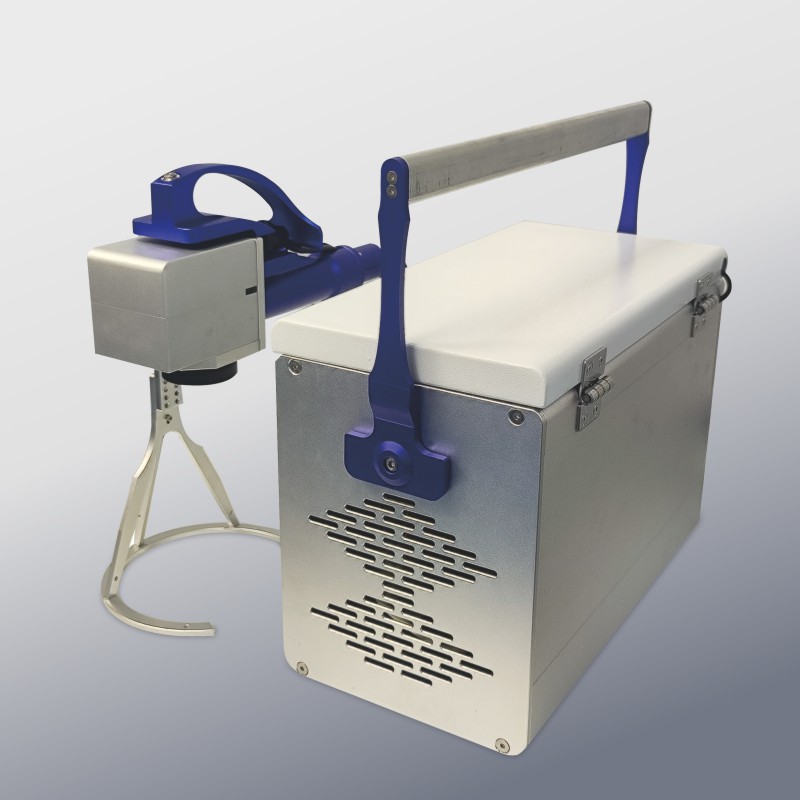

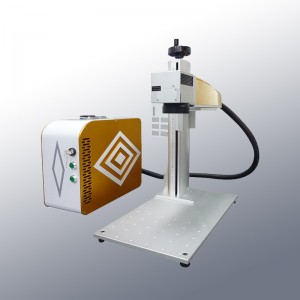

Handheld Optical Fiber Laser Marking Machine

✧ Machine Features

The marking accuracy is continuously improved, and the handheld laser marking machine will continue to speed up the efficiency during the welding process. Compared with traditional welding equipment, it is true that the accuracy and efficiency in all aspects will be greatly improved. Therefore, this is also trustworthy in the process of running. Only by mastering the leading level in design and strictly checking the process performance, can the factory configuration be higher.

The stability of the handheld laser marking machine will be guaranteed during the welding operation, and the overall welding cost will be lower. Only in this way, in the process of promoting and selling in the market, can we gain the trust and recognition of customers. Only when comparing the key points of welding, it can be seen that every detail must be grasped.

The handheld laser marking machine avoids the problems encountered in the traditional welding process. After the welding is completed, no grinding is required, and the molding will be more beautiful and unique. Therefore, this will also be very popular in the process of promoting sales in the market. Since the welding design requirements are relatively strict, the purpose is to reasonably grasp each process, so as to ensure that the quality of the factory will be better. Only considering the leading design and functional configuration in this aspect, it can be seen that the welding effect will be better.

✧ Application Advantages

Fast production

The processing speed is 2-3 times that of the traditional laser marking machine, excellent beam quality, small spot, narrow marking line width, suitable for fine marking.

Low cost of use

Low cost of use, power saving and energy saving, the power of the whole machine is only 500W. Compared with lamp pumping and semiconductor laser marking machines, it can save 20,000-30,000 yuan in electricity costs every year.

with high reliability

The laser all-fiber structure design ensures the high reliability of the laser without any optical components for collimation adjustment.

small size

Small size, no need for huge water cooling system, just simple air cooling. It can also work normally under certain harsh environments such as shock, vibration, high temperature or dust.

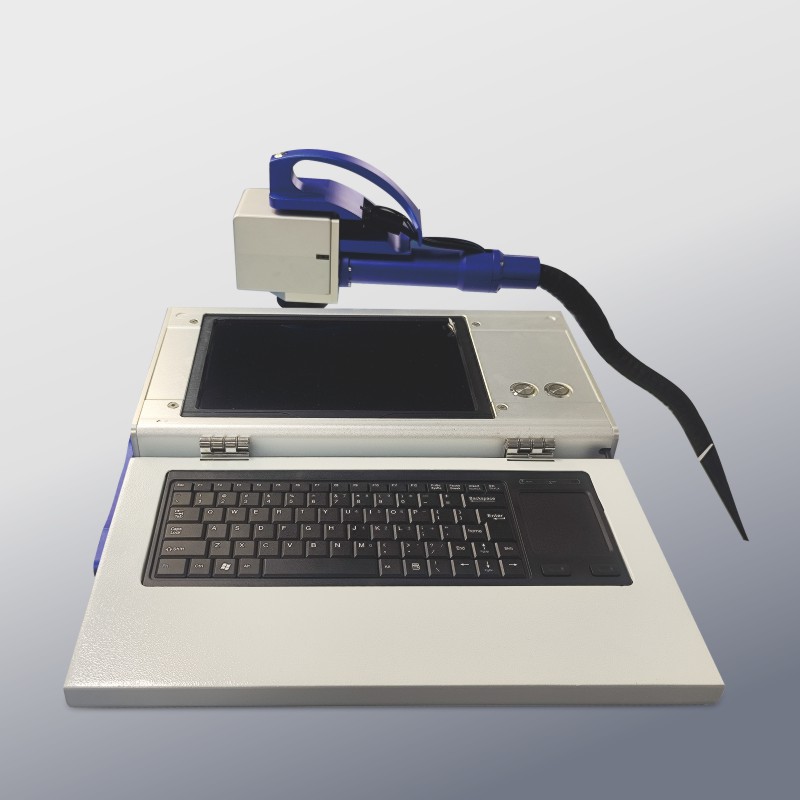

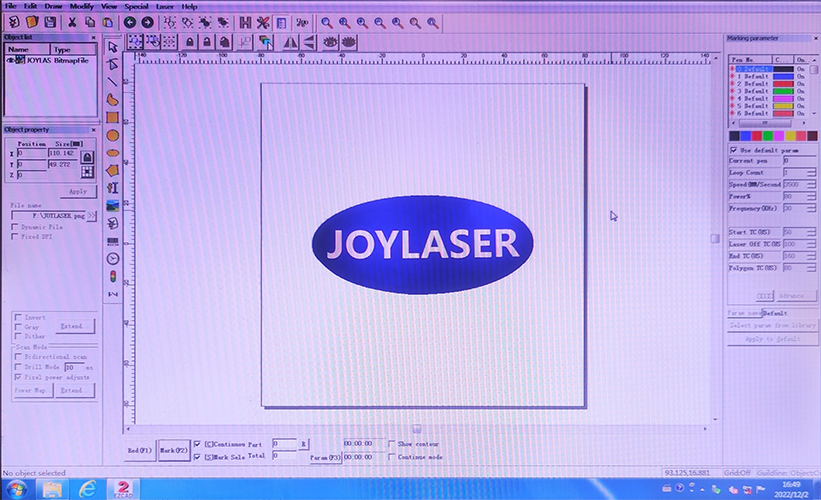

✧ Operation Interface

The software of JOYLASER marking machine needs to be used in conjunction with the hardware of the laser marking control card.

It supports various mainstream computer operating systems, multiple languages, and software secondary development.

It also supports common bar code and QR code , Code 39, Codabar, EAN, UPC, DATAMATRIX, QR CODE, etc.

There are also powerful graphics, bitmaps, vector maps, and text drawing and editing operations can also draw their own patterns.

✧ Technical Parameter

| Equipment model | JZ-FQ20 |

| Laser type | Fiber laser |

| Laser power | 20W |

| Laser wavelength | 1064nm |

| Laser frequency | 20-120KHz |

| Carving line speed | ≤7000mm/s |

| Minimum line width | 0.02mm |

| Repetition accuracy | ±0.1μm |

| Working voltage | AC220v/50-60Hz |

| Cooling mode | Air cooling |

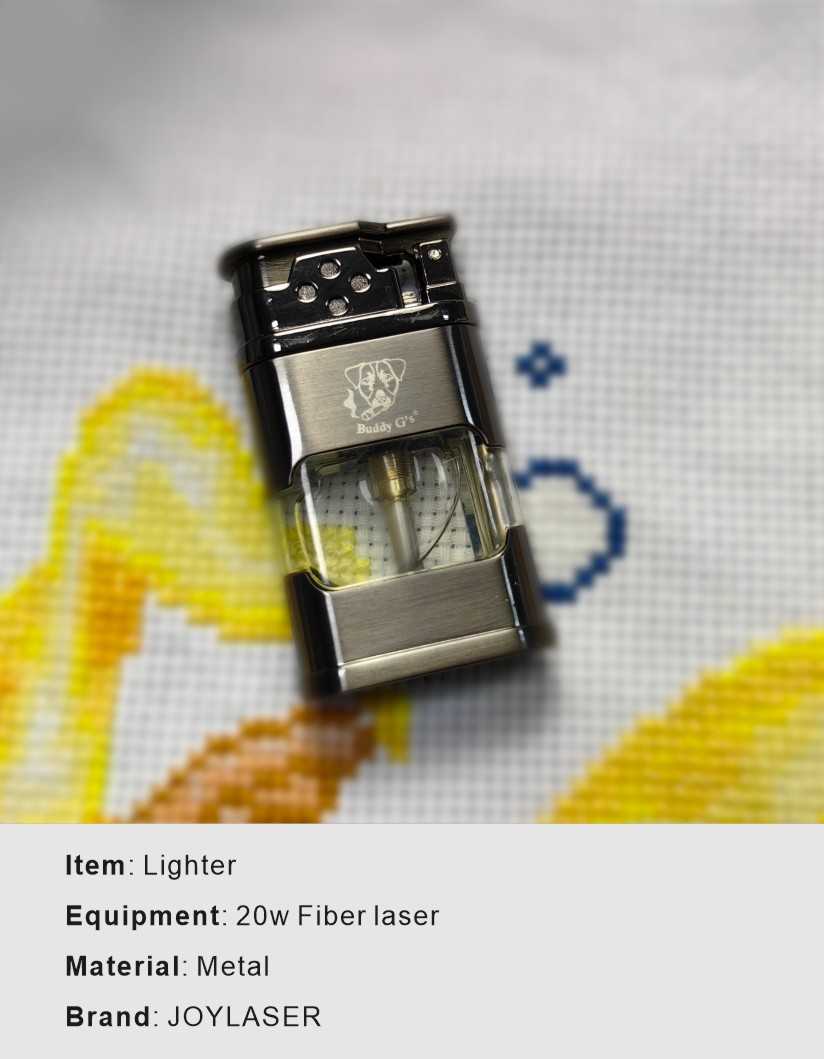

✧ Sample Of Product

Electronic and communication products, IC products, electric lines, cable computer components and electric appliance.Every kind of precision parts,hardware tools,instrument appliance,aviation and spaceflight appliance.Jewelry, garments, instruments, gifts, office devices, brand scutcheon, sanitary ware appliance.Dishware ,food ,drinking,smoking and alcohol,etc.