In modern industrial manufacturing, the progress of welding technology is of great significance. As an emerging technology, the handheld laser welding machine is transforming multiple industries.

The handheld laser welding machine has obvious advantages. It is easy to operate. Workers can operate it after simple training, reducing the dependence on highly skilled workers. The weld seam is beautiful and smooth, without the need for subsequent grinding, saving working hours and costs.

Its common technical parameters and performance indicators include: The laser power is usually between 1000W and 2000W, and can be selected as needed; the common laser wavelength is 1064nm; the welding speed can reach several meters per minute; the weld seam penetration can be adjusted; the heat-affected zone is very small.

In the automotive industry, both component welding and body repair can be used. For example, in frame welding, it can precisely control the weld seam and improve the stability of the frame. A car repair master feedback that body damage repair is faster and the traces are not obvious.

In the aerospace field, the welding of aircraft structural components and engine components has extremely high quality requirements. The handheld laser welding machine can weld high-strength materials, ensure the reliability of the aircraft structure, and also improve the performance and lifespan of the engine. Relevant reports show that after adopting this technology, the welding qualification rate of engine components has greatly increased.

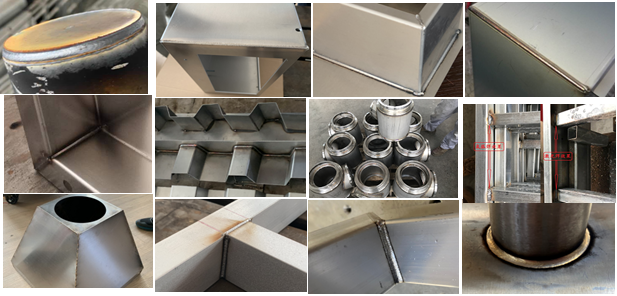

In the hardware industry, both the welding of hardware products and the repair of molds have their uses. A person in charge of a hardware products factory said that the product quality was recognized and orders increased.

In the tool industry, when manufacturing and repairing tools, it can quickly complete the welding to ensure strength and durability.

In the instrumentation industry, the welding of instrument housings and internal components relies on its seamless, high-precision, and low heat-affected zone characteristics.

Users' feedback is good. An engineer from an aerospace enterprise said that it has made a leap in the welding of aircraft components, with uniform weld seam penetration and controllable power density. Practitioners in the hardware industry lamented the saving of time and costs.

In conclusion, the handheld laser welding machine has the advantages of simple operation, beautiful weld seams, and low cost. It has broad prospects in fields such as automobiles, aerospace, hardware, tools, instrumentation, etc., and will bring high-quality welding solutions to more industries.

Post time: Jun-29-2024