In the field of modern industrial manufacturing, striving for excellent quality and efficient production processes is the continuous pursuit of enterprises. And when it comes to mold repair and manufacturing, our mold laser welding machines will be your best partners.

I. Precise Welding, Outstanding Quality

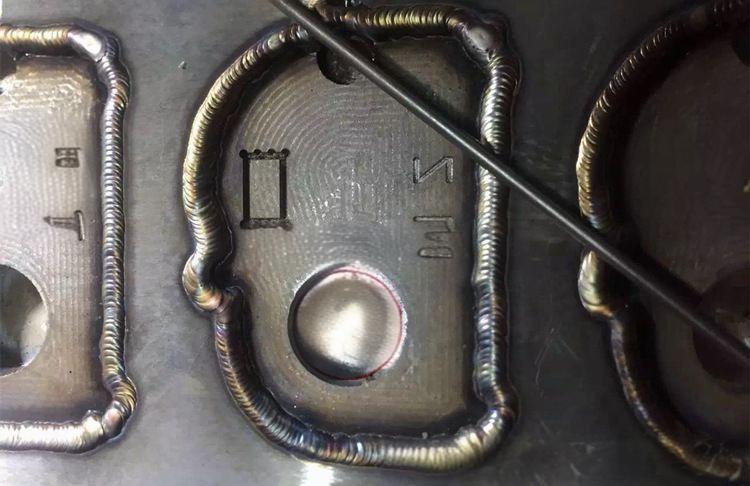

The mold laser welding machines adopt advanced laser technology and are capable of achieving high-precision welding. Compared with traditional welding methods, laser welding has a smaller heat-affected zone and can minimize damage to molds. This means that you can carry out rapid and accurate repairs and processing without affecting the overall performance of the molds.

Whether it's small precision molds or large and complex ones, our mold laser welding machines can handle them with ease. Their high-energy-density laser beams can penetrate various materials to achieve deep welding and ensure the strength and stability of the welded parts. Meanwhile, the precision of laser welding can reach the micron level, providing an unparalleled quality guarantee for your mold manufacturing.

The mold laser welding machines adopt advanced laser technology and are capable of achieving high-precision welding. Compared with traditional welding methods, laser welding has a smaller heat-affected zone and can minimize damage to molds. This means that you can carry out rapid and accurate repairs and processing without affecting the overall performance of the molds.

Whether it's small precision molds or large and complex ones, our mold laser welding machines can handle them with ease. Their high-energy-density laser beams can penetrate various materials to achieve deep welding and ensure the strength and stability of the welded parts. Meanwhile, the precision of laser welding can reach the micron level, providing an unparalleled quality guarantee for your mold manufacturing.

II. Efficient Production, Time-saving

In today's highly competitive market environment, time is money. The mold laser welding machines can significantly shorten the production cycle of molds with their high welding speeds. Compared with traditional welding methods, laser welding can complete a welding point within a few seconds, greatly improving production efficiency.

In addition, the mold laser welding machines also feature a high degree of automation. They can be used in conjunction with automated equipment such as robots to achieve unmanned production. This can not only reduce errors caused by manual operations but also further improve production efficiency and reduce production costs.

In today's highly competitive market environment, time is money. The mold laser welding machines can significantly shorten the production cycle of molds with their high welding speeds. Compared with traditional welding methods, laser welding can complete a welding point within a few seconds, greatly improving production efficiency.

In addition, the mold laser welding machines also feature a high degree of automation. They can be used in conjunction with automated equipment such as robots to achieve unmanned production. This can not only reduce errors caused by manual operations but also further improve production efficiency and reduce production costs.

III. Wide Applications, Meeting Various Needs

Our mold laser welding machines are applicable to various mold materials, including steel, iron, aluminum, copper, etc. Whether it's injection molds, die-casting molds or stamping molds, suitable welding solutions can be found.

For example, in the repair of injection molds, laser welding can quickly repair the worn surfaces of molds and extend their service lives. In the manufacturing of die-casting molds, laser welding can achieve welding of complex shapes and improve the precision and quality of molds. And in the production of stamping molds, laser welding can enhance the strength and durability of molds and reduce the frequency of mold replacement.

Our mold laser welding machines are applicable to various mold materials, including steel, iron, aluminum, copper, etc. Whether it's injection molds, die-casting molds or stamping molds, suitable welding solutions can be found.

For example, in the repair of injection molds, laser welding can quickly repair the worn surfaces of molds and extend their service lives. In the manufacturing of die-casting molds, laser welding can achieve welding of complex shapes and improve the precision and quality of molds. And in the production of stamping molds, laser welding can enhance the strength and durability of molds and reduce the frequency of mold replacement.

IV. Energy Saving, Environmental Protection, and Sustainable Development

The mold laser welding machines use clean energy - laser, and do not generate any harmful substances or exhaust emissions. Compared with traditional welding methods, laser welding is more energy-efficient and environmentally friendly, meeting the requirements of sustainable development in modern industry.

Moreover, laser welding has a high energy utilization rate and can greatly reduce energy consumption. This can not only save costs for you but also contribute to environmental protection.

The mold laser welding machines use clean energy - laser, and do not generate any harmful substances or exhaust emissions. Compared with traditional welding methods, laser welding is more energy-efficient and environmentally friendly, meeting the requirements of sustainable development in modern industry.

Moreover, laser welding has a high energy utilization rate and can greatly reduce energy consumption. This can not only save costs for you but also contribute to environmental protection.

V. Professional Services, Worry-free After-sales

We not only provide high-quality mold laser welding machines but also offer professional pre-sales consultations and after-sales services. Our technical team will provide customized welding solutions according to your specific needs. During the equipment installation and commissioning process, we will provide guidance throughout to ensure the normal operation of the equipment.

Meanwhile, we also provide equipment maintenance, repair and upgrade services to keep your mold laser welding machines in the best condition all the time. No matter when and where you encounter problems, our after-sales service team will respond promptly and solve the problems for you.

We not only provide high-quality mold laser welding machines but also offer professional pre-sales consultations and after-sales services. Our technical team will provide customized welding solutions according to your specific needs. During the equipment installation and commissioning process, we will provide guidance throughout to ensure the normal operation of the equipment.

Meanwhile, we also provide equipment maintenance, repair and upgrade services to keep your mold laser welding machines in the best condition all the time. No matter when and where you encounter problems, our after-sales service team will respond promptly and solve the problems for you.

All in all, our mold laser welding machines are industrial tools that integrate precise welding, efficient production, wide applications, energy saving, environmental protection and professional services. If you are looking for equipment that can improve the quality and efficiency of mold manufacturing, then the mold laser welding machine will be your best choice.

Post time: Dec-12-2024