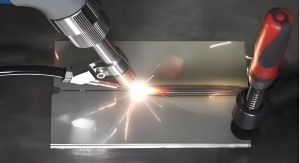

In today's advanced manufacturing field, the air-cooled handheld laser welding machine is becoming a popular choice for industrial welding with its excellent performance and significant advantages. So, what are its remarkable advantages? Let's explore.

I. Technical Specifications Parameters Show Strong Performance

- Laser power: The common laser power range is between 800W - 2000W, which can meet the welding requirements of different thicknesses and materials, providing sufficient energy for high-quality welding.

- Welding speed: Its welding speed can reach 5m/min - 10m/min, which greatly improves the production efficiency and shortens the production cycle.

- Spot diameter: The spot diameter is between 0.2mm - 2mm. Precise spot control can achieve fine and firm welding points.

- Operating frequency: The operating frequency is 20kHz - 50kHz. High-frequency operation ensures the continuity and stability of the welding process.

- Equipment weight: The weight of about 20kg - 60kg enables the operator to hold and operate it easily and flexibly deal with various welding scenarios.

- Size specifications: The compact design with a length of 50cm - 80cm, a width of 30cm - 50cm, and a height of 40cm - 60cm does not occupy too much space and is convenient to be arranged in different working environments.

- Power input requirements: Usually, it supports power input of 220V or 380V, adapting to a wide range of industrial power supply environments.

- Applicable range of welding materials: It is suitable for various common metal materials such as stainless steel, carbon steel, aluminum alloy, and copper, providing wide application possibilities for various industries.

- Equipment energy consumption data: Compared with traditional welding equipment, its energy consumption is significantly reduced, and it can save a lot of energy costs for enterprises during long-term operation.

II. A Powerful Tool for Improving Work Efficiency

The air-cooled handheld laser welding machine has significantly improved work efficiency with its outstanding performance. For example, in an automotive parts production enterprise, it takes several hours to complete the welding of a complex part by traditional welding methods. However, after adopting the air-cooled handheld laser welding machine, the welding time is shortened to tens of minutes. The fast welding speed and high-precision welding quality have greatly increased the one-time pass rate and reduced the time and resources wasted due to rework.

III. Significantly Reduce Costs

- n terms of energy consumption cost, efficient laser technology and optimized power management system make the air-cooled handheld laser welding machine have lower energy consumption during operation, and long-term use can save considerable electricity expenses.

- In terms of material cost, precise welding control reduces material loss during the welding process, improves material utilization, and reduces the purchase cost of raw materials.

- Maintenance costs are also greatly reduced. Its stable performance and simple structure reduce the frequency and cost of equipment failure and maintenance.

IV. Unparalleled Convenience in Operation

- The equipment's appearance design is ergonomic, the handle feels comfortable, and it is not easy to get fatigued during long-term operation.

- The human-computer interaction interface is simple and intuitive, and the operation buttons are clear and easy to understand, allowing operators to get started quickly.

- The intelligent parameter setting function enables operators to easily adjust welding parameters according to different welding tasks.

In conclusion, the air-cooled handheld laser welding machine has demonstrated significant advantages in the field of industrial welding with its powerful technical specifications, efficient working performance, remarkable cost savings and convenient operation methods. Whether it is to enhance production efficiency, reduce production costs, or offer a convenient operation experience, it is an ideal choice. It is believed that in the future, it will play an important role in more fields and promote the continuous development of the manufacturing industry.

Post time: Jul-09-2024