In today's industrial manufacturing field, continuous innovation and progress in technology have brought higher efficiency and quality to production. As an advanced welding equipment, the nanosecond laser welding machine is gradually becoming the first choice for many industrial manufacturers. Its characteristics of stable performance, low equipment energy consumption, and high welding quality have shown significant application advantages in fields such as automobiles, aerospace, and machinery.

I. Stable performance

The stable performance of the nanosecond laser welding machine is one of the important reasons for its popularity. The stability of long-term operation is one of its prominent manifestations. Even when working continuously for several hours or even days, the nanosecond laser welding machine can still maintain a stable welding effect, and there will be no performance degradation or failure caused by long-term operation.

In addition, the nanosecond laser welding machine has excellent adaptability to environmental changes. Whether in a high-temperature, high-humidity or low-temperature, dry environment, it can work normally without being disturbed by external environmental factors. This is particularly important in the aerospace field, because the manufacturing of spacecraft often needs to be carried out under extreme environmental conditions, and the nanosecond laser welding machine can ensure that the welding quality is not affected by the environment.

II. Low equipment energy consumption

Compared with traditional welding equipment, the nanosecond laser welding machine has obvious advantages in terms of energy consumption. According to statistics, the energy consumption of the nanosecond laser welding machine is about 30% lower than that of traditional arc welding equipment. This means that in the long-term production process, enterprises can greatly reduce energy costs.

This feature of low energy consumption not only brings direct economic benefits to enterprises, but also meets the requirements of energy conservation and environmental protection in today's society, and helps enterprises establish a good social image.

III. High welding quality

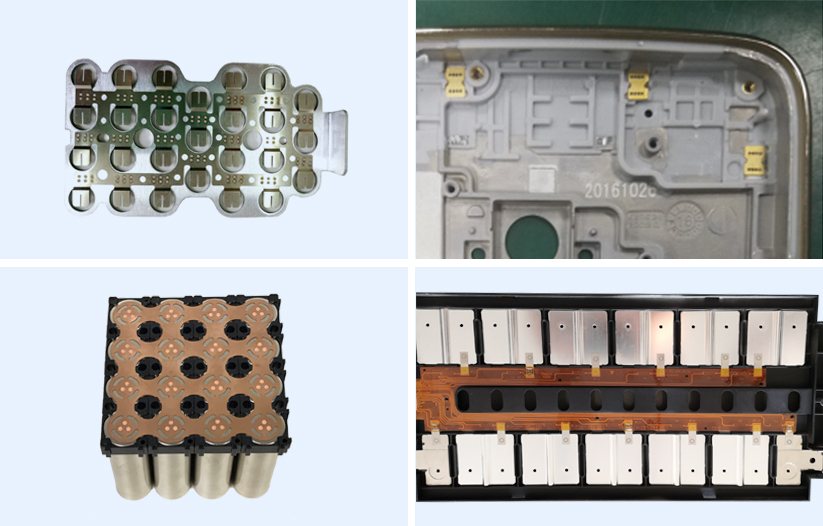

The nanosecond laser welding machine performs outstandingly in terms of welding quality, and can show its unique advantages whether in the welding of different materials or the application of complex processes.

In terms of the welding of different materials, the nanosecond laser welding machine can achieve high-quality welding of various metals and alloys, such as stainless steel, aluminum alloy, titanium alloy, etc. Whether it is a material with high hardness or a material with a low melting point, it can ensure the strength and tightness of the welded joint.

In the application of complex processes, the nanosecond laser welding machine can complete high-precision tasks such as thin-walled structure welding and micro-component welding. For precision components in the aerospace field, its welding accuracy can reach the micron level, ensuring the safety and reliability of aircraft.

If you are looking for an efficient and high-quality welding solution, you might consider the nanosecond laser welding machine, which will bring higher production efficiency and better product quality to your enterprise.

Post time: Jul-16-2024